SIJE: Driving Digital Transformation in Apparel Production with Monolis and Monolog

SIJE: Driving Digital Transformation in Apparel Production with Monolis and Monolog

Posted September. 08, 2025 13:45,

Updated September. 08, 2025 13:59

- SIJE specializes in digital transformation across the apparel supply chain,

offering Monolis, a SaaS-based solution for apparel sourcing and

production management, and Monolog, an IoT-based real-time productivity

monitoring solution.

- Over the past two years, SIJE has conducted proof-of-concept projects with 12

factories in Vietnam and a major Korean apparel company, boosting factory

productivity by more than 20% on average.

- Building on this success, the company has signed contracts with multiple

apparel firms and secured real-world adoption cases.

SIJE specializes in digital transformation across the apparel supply chain. It provides Monolis, a SaaS-based solution for apparel sourcing and production management, and Monolog, an IoT-based real-time productivity monitoring solution. Together, they enable digitalization throughout the entire apparel production process.

Over the past two years, SIJE has conducted proof-of-concept (PoC) projects with 12 factories in Vietnam and a major Korean apparel company, boosting factory productivity by more than 20% on average. Building on this success, the company has signed contracts with multiple apparel firms and secured real-world adoption cases. In November last year, SIJE opened a branch in Hanoi, Vietnam, and plans to expand into Indonesia and the United States in the first half of next year.

We spoke with SYNZUN, CEO of SIJE, about the company and its solutions Monolis and Monolog.

SYNZUN, CEO of SIJE / Source=IT donga

Challenges Witnessed on the Factory Floor Inspired the Founding of SIJE

Please introduce yourself.

I am SYNZUN, CEO of SIJE. After graduating from Hanyang University with a degree in Apparel Science, I worked for five years at GGM Trading as an industrial engineering researcher. I managed smart factory system projects in Vietnam and Indonesia, eventually becoming head of the Process Analysis Center (PAC).

The PAC analyzes and researches optimal production processes for apparel. Whenever design or fabric changes, it determines the best process, calculates working hours, manpower, and input costs, and derives production costs. It serves as a bridge between office operations and factories. In this role, I was able to take a broad view of supply chain operations, identify structural issues in the apparel industry, and decided to establish SIJE to solve them.

What problems did you identify?

Two major issues stood out. First was the structural vulnerability of the industry. During the COVID-19 pandemic, apparel trade was among the hardest hit. Our company at the time also suffered from sharp drops in orders. Experiencing this firsthand revealed fundamental weaknesses.

Traditionally, apparel has relied on low-cost manufacturing in developing countries, but this model is highly vulnerable to external shocks such as pandemics or tariffs. I realized that digitizing supply chains could help address these cost challenges.

Second was the lack of quantitative production management systems. Apparel factories run multiple lines, and to meet output targets efficiently, processing times must be standardized. Yet due to the labor-intensive nature of the industry, applying quantitative systems was difficult. While leading smart factory projects, I developed a device to measure worker output in real time. This demonstrated that with big data, production could be quantified and evaluated more clearly. However, as apparel manufacturing and trading were the company’s core businesses, investment in IT was limited.

Seeing peers succeed in startups motivated me to take the leap into entrepreneurship.

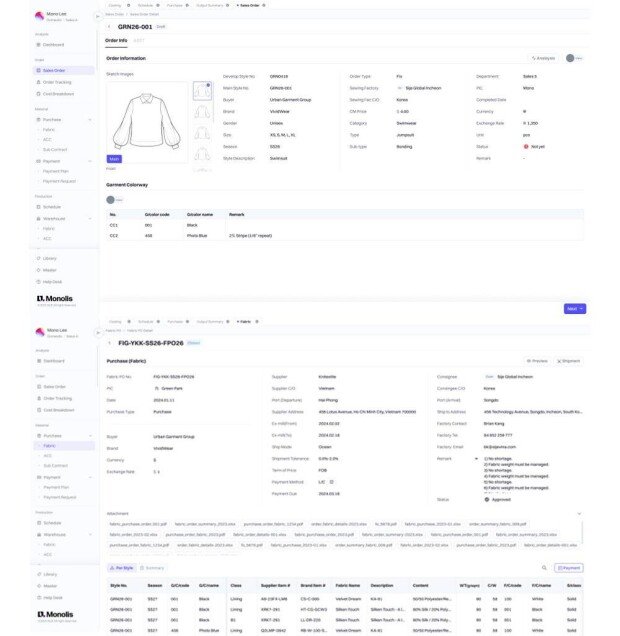

Automatic linkage of work orders in Monolis (top) and automated purchase order management system interface / Source=SIJE

Transforming Apparel Production with Monolis and Monolog

Please introduce SIJE.

SIJE is a company dedicated to digitalizing the apparel supply chain. Guided by the vision of making apparel a key industry of the future, we provide data-driven supply chain management solutions—Monolis and Monolog—that digitize manufacturing, processing, and shipping. The company name SIJE embodies our philosophy: based on the legacy of the past, we improve the present and create the future.

Tell us about your core solutions, Monolis and Monolog.

Monolis is a SaaS solution for apparel sourcing and production management. It digitizes outsourcing-based supply chain systems, reducing administrative tasks and cutting unnecessary costs.

Its defining feature is mapping technology. When companies request apparel production, they typically provide work orders, purchase orders (PO), bills of materials (BOM), and technical packages (TP). Each document contains 1,800–2,000 compliance items, often more depending on size, color, or pattern variations. We built a comprehensive map linking these items and processes together, allowing users to see the entire flow from work order to shipment. Creating this map alone took three years due to the complexity of the industry.

By uploading documents to Monolis, all necessary production information is automatically distributed and processed according to workflow. This reduces office work by about 65%. Managers only need to decide whether to proceed to the next step, without drafting reports. Tasks, their necessity, and next steps are easy to identify, while data errors are flagged immediately.

While developed for apparel, Monolis’s mapping technology can also be applied to other industries with layered supply chains. We are already in discussions with footwear and bag manufacturers about adoption.

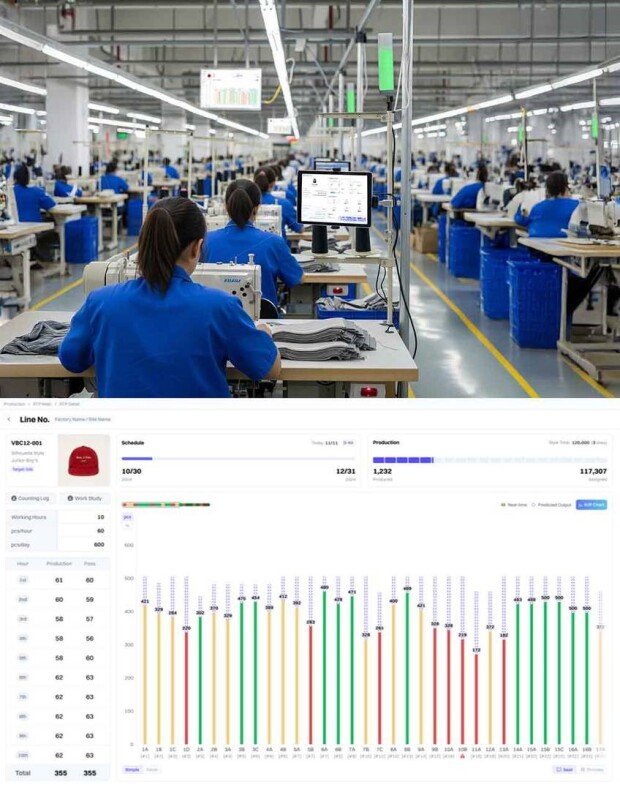

A factory using Monolog (top) and real-time production monitoring interface / Source=SIJE

Monolog is an execution management solution that uses IoT devices for real-time productivity monitoring and statistical analysis. Apparel is labor-intensive, making productivity visualization difficult, but we achieved it through big data.

It measures output and working time, then recommends optimal management strategies. It can suggest ideal production times or processes tailored to worker capabilities. Monolog has raised factory productivity by more than 15%, directly boosting sales.

In addition to Monolis and Monolog, we heard SIJE is preparing SIJE OS. What is it?

SIJE OS is an integrated AI agent for apparel supply chains, built on the data infrastructure of Monolis and Monolog. It supports production planning, sourcing, automated ordering, and simulations. It can predict bottlenecks and enable preemptive responses. Reports can be generated easily through an AI chatbot.

We developed SIJE OS for clients who only want to use selected functions. By integrating with their existing systems, they can still leverage Monolog’s core values such as data analytics and mapping. SIJE OS will be launched in the first half of 2026.

Before (top) and after applying Monolog at a large Vietnamese garment factory. Monolog enables visualization of worker productivity. / Source=SIJE

Proving Technology Through Partnerships with Vietnamese Factories and Korean Apparel Giants

Please update us on your business progress.

Over the past two years, we’ve conducted PoC projects in 12 factories in Vietnam, boosting productivity by more than 20% on average. In 2024, we also ran PoCs with major Korean apparel companies, achieving strong results. These accomplishments led to contracts with various apparel firms and real-world adoption.

In November last year, we opened a branch in Hanoi, Vietnam, and plan to establish branches in Indonesia and the United States in the first half of next year. This will accelerate expansion across Asia—including Indonesia, Bangladesh, and India—while also addressing demand in the U.S. fashion market.

You are currently supported by SeoulTech’s global collaboration program. What kind of support have you received?

We are participating in the Amazon Web Services (AWS) Jungle Program. Through this, we received AWS credits and, in May, visited AWS headquarters in the U.S. for training on solution building and B2B strategies. We gained valuable insights into the U.S. market and confirmed our potential to enter it. We also built networks with startup founders pursuing similar models. The program has been invaluable.

SYNZUN explaining SIJE, Monolis, and Monolog / Source=IT dongA

First, we will continue enhancing our solutions and adding new features, such as an automatic work order creation function. At the same time, we plan to expand into global markets like the United States to broaden our customer base.

We are also conducting a Series A funding round to accelerate AI model development and SIJE OS rollout. Last May, we completed a pre-Series A round worth 2 billion KRW.

Our ultimate goal is to build a SaaS model that integrates outsourcing industries across multiple countries into one unified system. Beyond apparel, we aim to expand into other manufacturing sectors, creating industrial environments less dependent on manual labor.

By Man-hyuk Han (mh@itdonga.com)

* This article was written with support from Seoul National University of Science and Technology.