Wooden rafts and LNG carriers

Wooden rafts and LNG carriers

Posted June. 19, 2020 07:36,

Updated June. 19, 2020 07:36

Two news articles have recently caught my eyes: One on the biggest deal on highly advanced LNG carriers and another on basic wooden rafts being designated as a fishing heritage. Three South Korean shipbuilding companies have signed a slot agreement with Qatar Petroleum to provide more than 100 LNG carriers by 2027, which is worth 23 trillion won. The three companies, which take up 90 percent of the global LNG carrier market, have made a deal on LNG carriers that are much more expensive than other oil tankers, reinforcing South Korea’s reputation as a shipbuilding powerhouse.

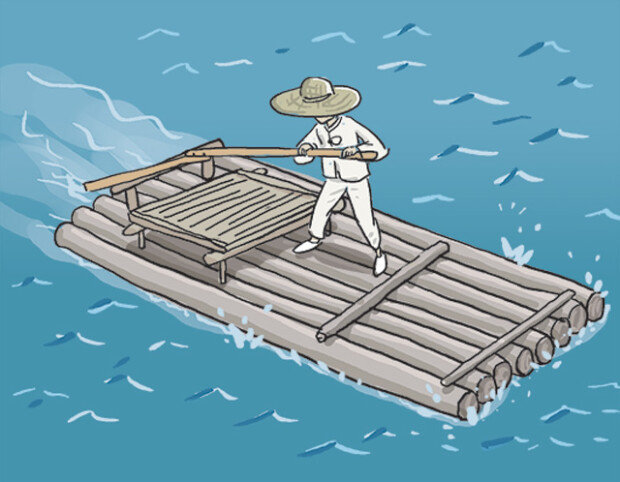

Another news covered the story of harvesting seaweed wooden rafts being designated as a fishing heritage. What does a country with the competitive shipbuilding industry that produces latest oil takers and LNG carriers have to do with wooden rafts? Wooden rafts are rafts made of logs. They are even simpler than a wooden ship from the 8th century) found in Donggung Palace and Wolji Pond in Gyeongju, which is made of wood slabs, an upgrade from dugouts. They are still used in some fishing towns, and the government is going to designate some of them as a national heritage. Tangible or intangible fishing skills and resources, which have been developed to adapt to local environments, society and traditions, are designated as a national fishing heritage by the minister of Oceans and Fisheries

I studied a fishing village off the coast of East Sea a few years ago. There were eight wooden rafts made by weaving together logs, but I did not pay much attention to them. One of the eight rafts belonged to an old couple, Mr. and Mrs. Kim, and was always out in the sea. They made ends meet by harvesting seaweed on the raft. One day, I struck up a conversation with Mr. Kim who was fixing the boat on the beach. He listed up all the strengths of rafts. “It’s got a flat platform, which makes it easy to navigate in shallow waters. Sharp edges may be good for propelling the boat, but they make your boat sink if it hits a rock,” he said. “This is not the case for wooden rafts because they are made of logs. They are also easier to work on because they are not affected by waves as much.” It made me realize the simple and basic wooden raft is irreplaceable.

Mr. Kim continued. Buoyancy is critical for safety because the raft should carry a large amount of seaweed. To achieve the level of buoyancy, Paulownia should be dried for two to three years after its skin is taken off. It is not difficult to build a wooden raft, but it takes patience as the wood must be completely dry. “People in our village plant Paulownia in advance to make wooden rafts. They cut it down and dry them for years. Wooden rafts are made with time. I am also drying Paulownia under a wall to replace this one I am fixing,” he said. He was suffering from decompression sickness from years of diving, and I was told he passed away not long after I left the village. The Paulownia under the wall is wasted, and the fixed raft has been pulled out onto the ground.