Leaflyze, "We Will Set a New Standard in the Sewing Industry with AI"

Leaflyze, "We Will Set a New Standard in the Sewing Industry with AI"

Posted November. 18, 2025 09:58,

Updated November. 18, 2025 10:25

- Leaflyze is a South Korean startup that aims to revolutionize the garment industry by integrating AI and robotics into sewing automation, drastically reducing production timelines and costs with its flagship service, Teddify.

- By directly operating its own manufacturing system, Leaflyze rapidly validates its technology and offers a new model that emphasizes speed, flexibility, and proximity to the market rather than relying on cheap labor.

- The company is now preparing for global expansion, leveraging its innovative approach to bring the garment industry back to Korea and potentially to other markets like Japan and the US.

South Korea's garment industry, born from the ashes of the 1950s Korean war, was a cornerstone of the 'Miracle on the Han River.' Fueled by abundant labor and cheap materials, Seoul's Pyeonghwa Market and Dongdaemun areas grew into a global apparel production hub from the 1960s to the 1980s. However, as labor costs surged, production bases shifted—first to China, then to Southeast Asia. Consequently, the domestic garment industry entered a path of decline.

Decades later, a deep-tech startup has stepped forward to revolutionize this industry with artificial intelligence (AI) and robotics: Leaflyze Inc. We met with CEO Jong-ho Park to discuss his business strategy and vision for the future.

From Academia to Entrepreneurship

Founded in 2024, Leaflyze is a startup developing AI-based sewing automation solutions. The company name combines 'Leaf' and 'Analyze.' According to CEO Park, the name signifies "analyzing fabric," as a leaf serves as a soft metaphor for textile.

Park, who majored in Computer Science at Seoul National University (SNU), specialized in AI and graphics in graduate school. After graduating, he joined SUALAB, a deep-learning machine vision startup, where he built AI programs that automated visual inspections using cameras. He then moved to Upstage, a startup specializing in Large Language Models (LLMs) and custom AI solutions. There, he developed Optical Character Recognition (OCR) solutions—which automatically recognize and convert text from images or documents—marking another period of professional growth.

"I joined SUALAB in its early days as a research staff member and worked incredibly hard," Park recalled. "I was very interested in how the programs I developed could actually change an industry, which motivated me to be more passionate." He continued, "Watching SUALAB's growth made me consider entrepreneurship. I judged that experiencing another leading AI startup would be beneficial, which led to my move to Upstage. After about a year and a half, I felt I was ready to start my own company and resigned."

After accumulating diverse experience at AI startups, Park explored various business ideas before focusing on the garment industry. He noted that despite its long, proven history of value, the industry was riddled with inefficiencies due to its "complex structure and entangled interests." Park identified 'process automation' as the fundamental solution. Believing the core technologies required aligned perfectly with his and his team's capabilities, he decided to found Leaflyze.

AI Experts Unite to Tackle Traditional Industry

Leaflyze is built around CEO Park, CTO Seung-hwan Lee (a Stanford University researcher in character animation and 3D vision AI), and CPO Jong-min Park (a KAIST alumnus who developed robot control systems). These three AI experts united to focus on innovating the entire garment manufacturing process with AI and robotics.

Leaflyze's flagship service is 'Teddify,' an ultra-fast sewing ODM (Original Design Manufacturing) service that manages the entire process from product development to production. It has achieved a significant breakthrough by reducing the conventional development and production timeline of over six months to just one month. "The market for merchandise (known as 'goods' in Korea), such as dolls, moves incredibly fast. Speed in development is a direct competitive advantage," Park said, emphasizing the importance of agile manufacturing.

A key feature of Teddify is its integration of digital twin technology. This technology creates an identical replica of a real-world object or system in a virtual space, using real-time data to run simulations, analyses, and predictions. Previously, clients had to wait 1-3 weeks each time they needed a new physical prototype (sample). With Teddify's virtual sample development system, they can review and revise a prototype's design in as little as one day, leading to high customer satisfaction.

Robot-based production process automation is another core element of Teddify. Leaflyze is automating the three stages of sewing—Cutting, Making (sewing), and Trimming—starting sequentially with cutting. The company is currently developing a remote automated cutting system using 'leader-follower robots.'

"When a person performs a task, a connected robot follows their exact movements and learns. This allows us to conduct production and data accumulation simultaneously," Park explained. "A robot cannot be autonomous from day one. It needs a period of data accumulation for training. However, it's crucial for us to be in production immediately. That’s why we developed the leader-follower robot."

He added, "Humans and robots work together, shortening the automation learning curve. This allows us to implement automation solutions without halting the production line. We plan to deploy the remote cutting system on-site starting early next year."

According to Leaflyze, Teddify can also solve the industry's chronic labor cost problem. The garment industry is typically labor-intensive, meaning labor accounts for a high percentage of production costs. This forced companies to move to low-wage countries, distancing them from their core markets and making it difficult to respond to trends.

"Teddify enables manpower reduction through robotic automation," Park emphasized. "By operating close to the market, we can reflect trends faster and drastically cut delivery times. This structure ensures we can be fully price-competitive."

Direct Application Over Tech Sales: A Faster Path to Validation

Park identifies 'direct operation' as Leaflyze's biggest differentiator. Most tech startups develop solutions to sell or license to existing players. Leaflyze, however, applies its solutions directly to its own manufacturing system. This allows the company to rapidly verify the practical value of its technology.

"Leaflyze has decided to become the entity that directly operates the manufacturing business," Park stated. "As a result, we can immediately measure how much our technology reduces costs and shortens timelines. Selling technology requires navigating multiple stages: value verification, raising industry awareness, and establishing the right conditions. We believe our direct operation model is ultimately the faster path to confirming the technology's true value."

Leaflyze is seeing a growing number of custom orders, from corporate merchandise and hotel fixtures to 'robot wear.' Client feedback is positive, citing the reduced production time and lower costs. Furthermore, the company is developing and producing its own product lines. The tiger and rabbit dolls are flagship examples. "Since our mission is to re-establish a hub for the Korean garment industry, we are developing products with a distinctly Korean theme," Park explained. "We plan to commercialize a tiger from the 'Hojakdo' and a rabbit from the 'Togudo,' both inspired by traditional Korean folk paintings (Minhwa)."

In this way, Leaflyze competes with technology, not labor costs. It proposes a new model—fast, flexible, and close to the market—to lure the garment industry back to Korea.

But the path wasn't easy. Leaflyze faced numerous trials from its inception. "We had no experience in garment manufacturing," Park recalled. "The necessary know-how couldn't be found in research papers or through web searches, which made it harder." He added, "We learned firsthand through many sewing mistakes. If the sequence was wrong or the method was different, the result was inevitably a failure."

Realizing they needed the tacit knowledge of industry veterans, Park sought them out. By demonstrating their "sincerity", Leaflyze gradually built a network of collaborators. By learning from these experts, the team identified which parts of the process would be most innovative to automate and applied this to Teddify.

The company posted a "Help Wanted" ad on Karrot (formerly Daangn Market) reading, "People who can make dolls," and even put up a sandwich board outside their office saying, "Seamstresses Wanted." They hired experienced sewers on a part-time basis, working alongside them to absorb their know-how.

"Our biggest concern was whether we could rebuild a professional sewing workforce in Korea. But we were pleasantly surprised by how many skilled technicians responded," Park said. "There has been a strong perception that sewing is low-paid work. However, because we reduce unnecessary costs with technology, we strive to provide appropriate compensation. We believe this change is essential for a new generation to want to enter the garment industry."

A Strategic Eye on Global Expansion

Leaflyze expects to cross its break-even point this year. "It is notoriously difficult for a manufacturing business to break even within two years. For us, having not even been in the industry, to achieve this within our first year is a significant accomplishment in itself," Park stated.

The company's current challenge is scaling. Leaflyze is considering acquiring or establishing a new factory and is developing its own systems to manage personnel and production status. "When we scale, new problems will inevitably arise. The most important thing is to prepare for them well. We still have many solutions to test and verify, but we will build them out one by one," Park said.

Leaflyze dreams of expanding its 'Made in Market' strategy globally. "The garment industry has continuously moved in pursuit of lower labor costs—from Korea to China, and then to Southeast Asia. But the further you get from the market, the slower the communication and the greater the inefficiency. The fundamental solution is to increase efficiency with technology near the market," Park said.

He explained, "If automation reduces the reliance on manpower, the total production cost decreases. When you factor in the savings on logistics, customs, and warehousing, our costs can become comparable to, or even lower than, manufacturing in Southeast Asia." Park concluded, "If we can establish a competitive price point in Seoul, we can apply the same model in Tokyo or New York. After we validate our minimal-labor automation model in Korea, we will look to Japan for our first overseas expansion."

Recognizing its growth potential, Leaflyze was selected for the "Global Competency Enhancement Program" of the Early-Stage Startup Package, run by SeoulTech (Seoul National University of Science and Technology). "We received commercialization funding, which was a great help in building the remote automated cutting system," Park said. "The program also provided networking opportunities, which allowed us to explore avenues for global expansion."

Finally, Park reiterated his mission: "Korea's garment industry may have declined, but Leaflyze wants to be the one to revive it. Our goal is to create the new standard for the sewing industry."

By Kui-im Park (luckyim@itdonga.com)

- By directly operating its own manufacturing system, Leaflyze rapidly validates its technology and offers a new model that emphasizes speed, flexibility, and proximity to the market rather than relying on cheap labor.

- The company is now preparing for global expansion, leveraging its innovative approach to bring the garment industry back to Korea and potentially to other markets like Japan and the US.

South Korea's garment industry, born from the ashes of the 1950s Korean war, was a cornerstone of the 'Miracle on the Han River.' Fueled by abundant labor and cheap materials, Seoul's Pyeonghwa Market and Dongdaemun areas grew into a global apparel production hub from the 1960s to the 1980s. However, as labor costs surged, production bases shifted—first to China, then to Southeast Asia. Consequently, the domestic garment industry entered a path of decline.

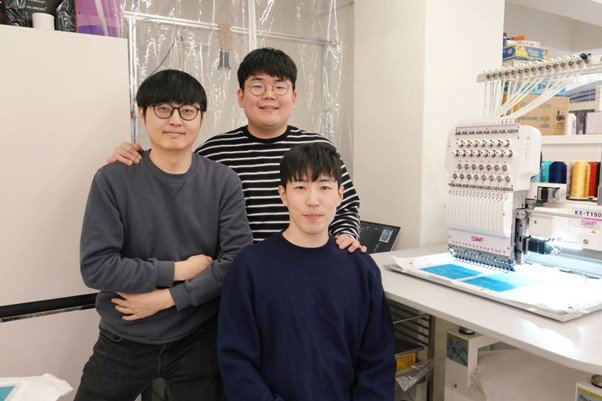

Jong-ho Park, CEO of Leaflyze / source=IT dongA

Decades later, a deep-tech startup has stepped forward to revolutionize this industry with artificial intelligence (AI) and robotics: Leaflyze Inc. We met with CEO Jong-ho Park to discuss his business strategy and vision for the future.

From Academia to Entrepreneurship

Founded in 2024, Leaflyze is a startup developing AI-based sewing automation solutions. The company name combines 'Leaf' and 'Analyze.' According to CEO Park, the name signifies "analyzing fabric," as a leaf serves as a soft metaphor for textile.

Park, who majored in Computer Science at Seoul National University (SNU), specialized in AI and graphics in graduate school. After graduating, he joined SUALAB, a deep-learning machine vision startup, where he built AI programs that automated visual inspections using cameras. He then moved to Upstage, a startup specializing in Large Language Models (LLMs) and custom AI solutions. There, he developed Optical Character Recognition (OCR) solutions—which automatically recognize and convert text from images or documents—marking another period of professional growth.

"I joined SUALAB in its early days as a research staff member and worked incredibly hard," Park recalled. "I was very interested in how the programs I developed could actually change an industry, which motivated me to be more passionate." He continued, "Watching SUALAB's growth made me consider entrepreneurship. I judged that experiencing another leading AI startup would be beneficial, which led to my move to Upstage. After about a year and a half, I felt I was ready to start my own company and resigned."

After accumulating diverse experience at AI startups, Park explored various business ideas before focusing on the garment industry. He noted that despite its long, proven history of value, the industry was riddled with inefficiencies due to its "complex structure and entangled interests." Park identified 'process automation' as the fundamental solution. Believing the core technologies required aligned perfectly with his and his team's capabilities, he decided to found Leaflyze.

AI Experts Unite to Tackle Traditional Industry

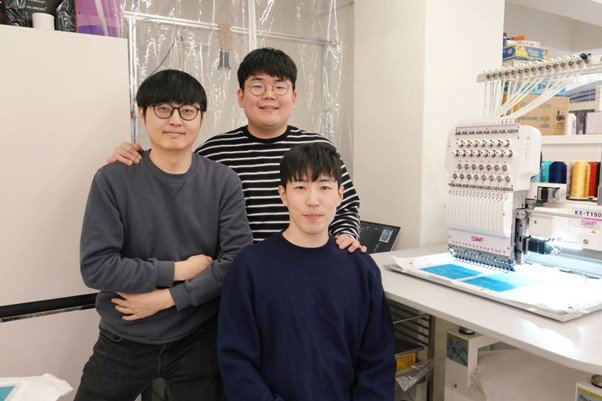

(Clockwise from left) CPO Jong-min Park, CTO Seung-hwan Lee, CEO Jong-ho Park / source=IT dongA

Leaflyze is built around CEO Park, CTO Seung-hwan Lee (a Stanford University researcher in character animation and 3D vision AI), and CPO Jong-min Park (a KAIST alumnus who developed robot control systems). These three AI experts united to focus on innovating the entire garment manufacturing process with AI and robotics.

Leaflyze's flagship service is 'Teddify,' an ultra-fast sewing ODM (Original Design Manufacturing) service that manages the entire process from product development to production. It has achieved a significant breakthrough by reducing the conventional development and production timeline of over six months to just one month. "The market for merchandise (known as 'goods' in Korea), such as dolls, moves incredibly fast. Speed in development is a direct competitive advantage," Park said, emphasizing the importance of agile manufacturing.

A key feature of Teddify is its integration of digital twin technology. This technology creates an identical replica of a real-world object or system in a virtual space, using real-time data to run simulations, analyses, and predictions. Previously, clients had to wait 1-3 weeks each time they needed a new physical prototype (sample). With Teddify's virtual sample development system, they can review and revise a prototype's design in as little as one day, leading to high customer satisfaction.

Customers can use Teddify to quickly review and modify virtualized prototypes, avoiding the 1-3 week wait for physical samples / source=Leaflyze

Robot-based production process automation is another core element of Teddify. Leaflyze is automating the three stages of sewing—Cutting, Making (sewing), and Trimming—starting sequentially with cutting. The company is currently developing a remote automated cutting system using 'leader-follower robots.'

"When a person performs a task, a connected robot follows their exact movements and learns. This allows us to conduct production and data accumulation simultaneously," Park explained. "A robot cannot be autonomous from day one. It needs a period of data accumulation for training. However, it's crucial for us to be in production immediately. That’s why we developed the leader-follower robot."

He added, "Humans and robots work together, shortening the automation learning curve. This allows us to implement automation solutions without halting the production line. We plan to deploy the remote cutting system on-site starting early next year."

According to Leaflyze, Teddify can also solve the industry's chronic labor cost problem. The garment industry is typically labor-intensive, meaning labor accounts for a high percentage of production costs. This forced companies to move to low-wage countries, distancing them from their core markets and making it difficult to respond to trends.

"Teddify enables manpower reduction through robotic automation," Park emphasized. "By operating close to the market, we can reflect trends faster and drastically cut delivery times. This structure ensures we can be fully price-competitive."

Direct Application Over Tech Sales: A Faster Path to Validation

Park identifies 'direct operation' as Leaflyze's biggest differentiator. Most tech startups develop solutions to sell or license to existing players. Leaflyze, however, applies its solutions directly to its own manufacturing system. This allows the company to rapidly verify the practical value of its technology.

"Leaflyze has decided to become the entity that directly operates the manufacturing business," Park stated. "As a result, we can immediately measure how much our technology reduces costs and shortens timelines. Selling technology requires navigating multiple stages: value verification, raising industry awareness, and establishing the right conditions. We believe our direct operation model is ultimately the faster path to confirming the technology's true value."

Tiger (left) and rabbit (right) dolls developed and produced by Leaflyze, soon to be commercialized / source=Leaflyze

Leaflyze is seeing a growing number of custom orders, from corporate merchandise and hotel fixtures to 'robot wear.' Client feedback is positive, citing the reduced production time and lower costs. Furthermore, the company is developing and producing its own product lines. The tiger and rabbit dolls are flagship examples. "Since our mission is to re-establish a hub for the Korean garment industry, we are developing products with a distinctly Korean theme," Park explained. "We plan to commercialize a tiger from the 'Hojakdo' and a rabbit from the 'Togudo,' both inspired by traditional Korean folk paintings (Minhwa)."

In this way, Leaflyze competes with technology, not labor costs. It proposes a new model—fast, flexible, and close to the market—to lure the garment industry back to Korea.

But the path wasn't easy. Leaflyze faced numerous trials from its inception. "We had no experience in garment manufacturing," Park recalled. "The necessary know-how couldn't be found in research papers or through web searches, which made it harder." He added, "We learned firsthand through many sewing mistakes. If the sequence was wrong or the method was different, the result was inevitably a failure."

Realizing they needed the tacit knowledge of industry veterans, Park sought them out. By demonstrating their "sincerity", Leaflyze gradually built a network of collaborators. By learning from these experts, the team identified which parts of the process would be most innovative to automate and applied this to Teddify.

Leaflyze not only creates a better environment for sewing technicians but also builds competitiveness by accumulating skills in tasks difficult for robots to replace / source=IT dongA

The company posted a "Help Wanted" ad on Karrot (formerly Daangn Market) reading, "People who can make dolls," and even put up a sandwich board outside their office saying, "Seamstresses Wanted." They hired experienced sewers on a part-time basis, working alongside them to absorb their know-how.

"Our biggest concern was whether we could rebuild a professional sewing workforce in Korea. But we were pleasantly surprised by how many skilled technicians responded," Park said. "There has been a strong perception that sewing is low-paid work. However, because we reduce unnecessary costs with technology, we strive to provide appropriate compensation. We believe this change is essential for a new generation to want to enter the garment industry."

A Strategic Eye on Global Expansion

Leaflyze expects to cross its break-even point this year. "It is notoriously difficult for a manufacturing business to break even within two years. For us, having not even been in the industry, to achieve this within our first year is a significant accomplishment in itself," Park stated.

The company's current challenge is scaling. Leaflyze is considering acquiring or establishing a new factory and is developing its own systems to manage personnel and production status. "When we scale, new problems will inevitably arise. The most important thing is to prepare for them well. We still have many solutions to test and verify, but we will build them out one by one," Park said.

Leaflyze dreams of expanding its 'Made in Market' strategy globally. "The garment industry has continuously moved in pursuit of lower labor costs—from Korea to China, and then to Southeast Asia. But the further you get from the market, the slower the communication and the greater the inefficiency. The fundamental solution is to increase efficiency with technology near the market," Park said.

He explained, "If automation reduces the reliance on manpower, the total production cost decreases. When you factor in the savings on logistics, customs, and warehousing, our costs can become comparable to, or even lower than, manufacturing in Southeast Asia." Park concluded, "If we can establish a competitive price point in Seoul, we can apply the same model in Tokyo or New York. After we validate our minimal-labor automation model in Korea, we will look to Japan for our first overseas expansion."

Recognizing its growth potential, Leaflyze was selected for the "Global Competency Enhancement Program" of the Early-Stage Startup Package, run by SeoulTech (Seoul National University of Science and Technology). "We received commercialization funding, which was a great help in building the remote automated cutting system," Park said. "The program also provided networking opportunities, which allowed us to explore avenues for global expansion."

Finally, Park reiterated his mission: "Korea's garment industry may have declined, but Leaflyze wants to be the one to revive it. Our goal is to create the new standard for the sewing industry."

By Kui-im Park (luckyim@itdonga.com)