K-Nano Aims for Real-Time Monitoring for Industrial Process Using Aerosol Technology

K-Nano Aims for Real-Time Monitoring for Industrial Process Using Aerosol Technology

Posted December. 11, 2025 15:06,

Updated December. 11, 2025 15:08

- K-Nano, a South Korean startup founded by Dong-bin Kwak, has developed an innovative real-time monitoring device using aerosol technology to analyze ultrafine particles and ions in industrial liquid processes, particularly for the semiconductor industry.

- Their technology enables rapid, accurate detection of particles as small as 1 nm, overcoming the limitations of traditional methods like ICP-MS, and is now moving toward commercialization in partnership and with support from institutions such as K-water and SeoulTech.

- K-Nano aims to expand its applications beyond semiconductors to other high-tech industries and is preparing for global market entry and mass production.

“The technology of aerosolization and ultrafine particle analysis is crucial across various fields, including environmental and atmospheric science, biotech, and engineering. K-Nano, a South Korean startup, has optimized this technology for use in liquid process quality control within high-value industries like semiconductors. While many companies pursue similar concepts, only a handful have successfully implemented them. K-Nano’s achievement is particularly significant as it represents the localization of this critical technology.”

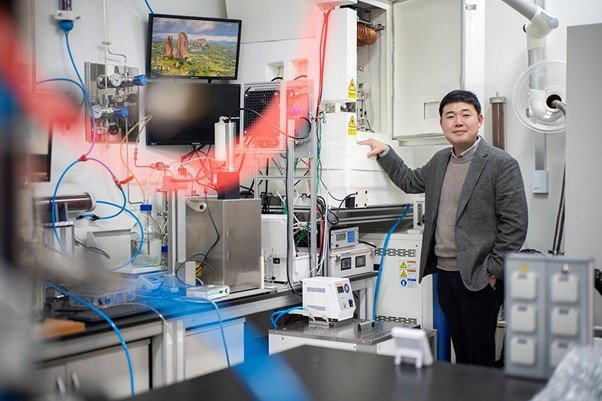

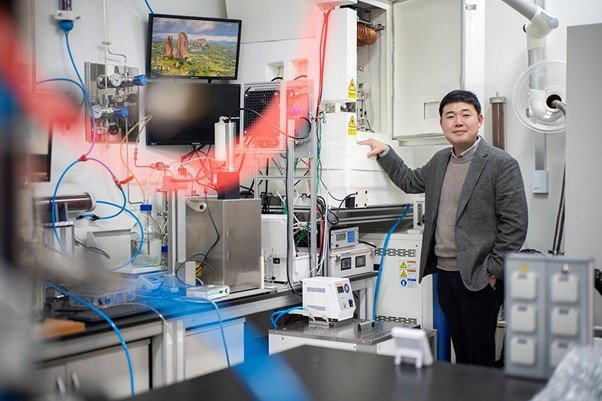

Dong-bin Kwak, CEO of K-Nano and an Assistant Professor in the MSDE Department at Seoul National University of Science and Technology (SeoulTech), established the company following a distinguished academic path. After earning his Ph.D. in Mechanical Engineering from the University of Minnesota in 2023, he joined SeoulTech in 2024. Kwak, who also directs the Nanoparticle Engineering Lab—a facility dedicated to analyzing fluid particles at the nanometer scale—is a visionary academic-turned-entrepreneur who brought his own ideas to industry.

Spearheading the Global Market with Aerosol-Based Monitoring

Kwak's entrepreneurial idea for K-Nano stemmed from his industry experience post-Ph.D., specifically his work in industry-academia collaboration at Applied Materials and subsequently at semiconductor equipment company Onto Innovation.

"At Applied Materials, I was involved with semiconductor process equipment and, through that work, conceived the idea of utilizing aerosols to analyze ultrafine particles in ultrapure water (UPW) for semiconductor cleaning processes in real time," Kwak explained, recounting his motivation for starting a faculty-le

d venture. "R&D engineers around me affirmed its high business potential."

K-Nano’s flagship product is a real-time monitoring device designed to complement traditional industrial liquid monitoring systems, such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS). ICP-MS functions by ionizing atoms in liquid samples using high-temperature plasma and then using a mass spectrometer to measure trace levels of elements. It is utilized across R&D and industrial sectors, including semiconductors, medicine, pharmaceuticals, and chemistry.

Kwak highlighted the limitations of the conventional approach: “While ICP-MS is used in nearly all R&D facilities, its high cost necessitates shared use, and specialized expertise is required for handling. Furthermore, sample preparation and analysis typically take three to five days, making rapid response in industrial settings difficult.”

K-Nano’s innovation lies in its aerosol-based technology for real-time analysis. “Existing real-time liquid particle counters analyze results based on the degree of light scattering when a laser is fired into the liquid. This method is prone to noise from submerged air bubbles and cannot accurately measure particles as small as 20 nm or detect ions,” Kwak noted. “By converting the liquid sample into a gaseous aerosol state for detection, we can measure particles down to 1 nm, as well as ions and multi-particles.”

For example, when analyzing a muddy, salty water sample, traditional hydro-sol methods (laser scattering) can only detect the solid mud particles, not the dissolved salt ions. ICP-MS can accurately measure both but is not real-time. K-Nano's system, by converting the hydro-sol into a gaseous aerosol, can measure both salt ions and mud particles, classifying them by size.

“The drawback is that it cannot precisely determine the origin of the detected sodium ions—whether they come from salt or, say, instant ramen seasoning,” Kwak added. “Our device is intended as a complementary, real-time monitoring tool rather than a primary, precision diagnostic tool.”

Contributing to Technology Localization and Commercialization

K-Nano has already completed a prototype of its aerosol-based equipment, confirming its potential in semiconductor production processes. It is now moving toward commercialization in partnership.“We have secured patents for the sensor unit and plan to integrate our proprietary software. K-Nano will be responsible for maintenance, developing process recipes, and other specialized tasks moving forward.” Kwak explained.

The company’s entry into the commercialization phase has attracted support from key institutions, including the Korea Water Resources Corporation (K-water). K-water has been actively supporting R&D to secure domestic UPW equipment for the semiconductor industry for nearly a decade, aiming for a 90% domestic self-sufficiency rate by 2030, up from the current 70%.

K-Nano was recognized with the Excellence Award in the commercialization category at the 2025 Korea Start-UP Water in September. This success grants the company access to the "K-Testbed" performance testing facilities, support for participating in domestic and international exhibitions to scout new markets, and assistance in attracting investment through the Water Industry Fund.

SeoulTech’s Startup Support Foundation is also fostering K-Nano's growth. Kwak stated, “We’ve received multifaceted business and financial support, including the preliminary startup package. Our recent demo day provided opportunities to receive investment recommendations and feedback from investors. The foundation continues to provide platforms for business expansion, such as an invitation to the 2025 Creative Capacity Building Networking event on December 12th.”

The foundation also supported K-Nano’s participation in ILS 2025 (Innovation Leaders Summit) in Japan, one of Asia’s largest open innovation trade shows. Kwak mentioned, “From December 1st to 5th, we participated in ILS 2025, facilitating collaboration opportunities with major Japanese corporations. We discussed partnerships with companies such as Intercompo, Tokyo Electron, and YUASA Trading.”

Semiconductors as a Beachhead to Broader Industrial Adoption

K-Nano’s current aerosol monitoring device is specifically targeted at semiconductor manufacturers. Kwak is confident that success in the challenging semiconductor market will pave the way for adoption across other high-tech manufacturing sectors—including secondary batteries, displays, biotechnology, pharmaceuticals, precision chemistry, food, and cosmetics.

Kwak’s decision to tackle the semiconductor industry first stems from his background as a researcher at the Center for Filtration Research (CFR), where he focuses on the theory of filter media and system performance, as well as establishing filtration systems.

While CFR primarily involves environmental and consumer electronics companies, its roster also includes industry giants such as Applied Materials, Samsung Electronics, and LG Electronics, alongside filtration specialists like Pall Corporation, cleanroom air monitoring companies like TSI, and material simulation firms like Math2Market. Kwak plans to leverage his involvement in CFR research projects and networking to stay abreast of technological trends and promote K-Nano's capabilities to semiconductor firms.

K-Nano’s goal for the coming year is the successful mass production of its product and its introduction into manufacturing processes, coupled with generating overseas demand.

“K-water’s support for domestic UPW technology has helped Korean companies gain international recognition,” Kwak stated. “Next year, our goal is to build a mass-production model and implement it in actual production lines. Based on that success, we plan to introduce the product to international companies. In 2027, we aim to participate in the UltraFacility Conference, the world's largest semiconductor monitoring equipment exhibition, to promote K-Nano's technology and strive to establish ourselves as the standard technology for liquid monitoring across various industries.”

By Si-Hyeon Nam (sh@itdonga.com)

- Their technology enables rapid, accurate detection of particles as small as 1 nm, overcoming the limitations of traditional methods like ICP-MS, and is now moving toward commercialization in partnership and with support from institutions such as K-water and SeoulTech.

- K-Nano aims to expand its applications beyond semiconductors to other high-tech industries and is preparing for global market entry and mass production.

“The technology of aerosolization and ultrafine particle analysis is crucial across various fields, including environmental and atmospheric science, biotech, and engineering. K-Nano, a South Korean startup, has optimized this technology for use in liquid process quality control within high-value industries like semiconductors. While many companies pursue similar concepts, only a handful have successfully implemented them. K-Nano’s achievement is particularly significant as it represents the localization of this critical technology.”

Dong-bin Kwak, CEO of K-Nano and Assistant Professor of SeoulTech / source=IT dongA

Dong-bin Kwak, CEO of K-Nano and an Assistant Professor in the MSDE Department at Seoul National University of Science and Technology (SeoulTech), established the company following a distinguished academic path. After earning his Ph.D. in Mechanical Engineering from the University of Minnesota in 2023, he joined SeoulTech in 2024. Kwak, who also directs the Nanoparticle Engineering Lab—a facility dedicated to analyzing fluid particles at the nanometer scale—is a visionary academic-turned-entrepreneur who brought his own ideas to industry.

Spearheading the Global Market with Aerosol-Based Monitoring

Kwak's entrepreneurial idea for K-Nano stemmed from his industry experience post-Ph.D., specifically his work in industry-academia collaboration at Applied Materials and subsequently at semiconductor equipment company Onto Innovation.

"At Applied Materials, I was involved with semiconductor process equipment and, through that work, conceived the idea of utilizing aerosols to analyze ultrafine particles in ultrapure water (UPW) for semiconductor cleaning processes in real time," Kwak explained, recounting his motivation for starting a faculty-le

d venture. "R&D engineers around me affirmed its high business potential."

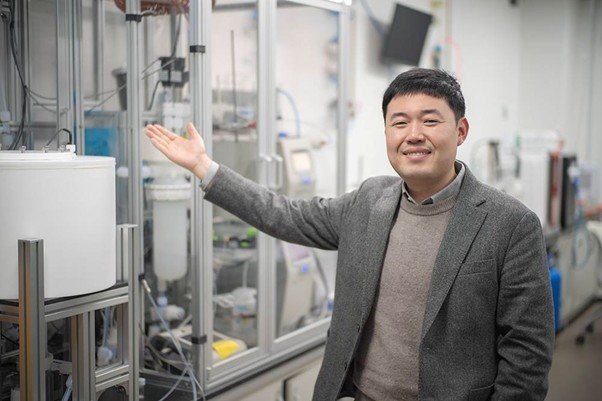

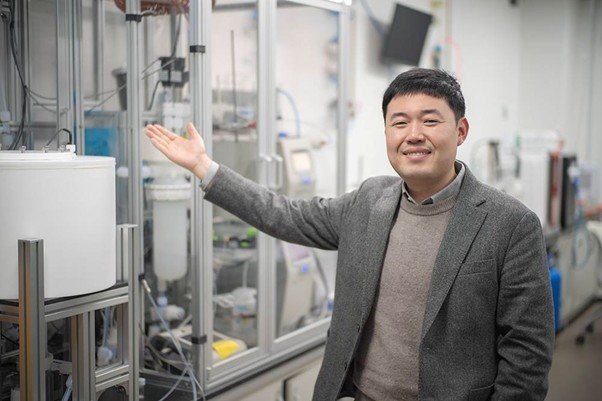

Kwak is introducing Aerosol monitoring devices / source=IT dongA

K-Nano’s flagship product is a real-time monitoring device designed to complement traditional industrial liquid monitoring systems, such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS). ICP-MS functions by ionizing atoms in liquid samples using high-temperature plasma and then using a mass spectrometer to measure trace levels of elements. It is utilized across R&D and industrial sectors, including semiconductors, medicine, pharmaceuticals, and chemistry.

Kwak highlighted the limitations of the conventional approach: “While ICP-MS is used in nearly all R&D facilities, its high cost necessitates shared use, and specialized expertise is required for handling. Furthermore, sample preparation and analysis typically take three to five days, making rapid response in industrial settings difficult.”

K-Nano’s innovation lies in its aerosol-based technology for real-time analysis. “Existing real-time liquid particle counters analyze results based on the degree of light scattering when a laser is fired into the liquid. This method is prone to noise from submerged air bubbles and cannot accurately measure particles as small as 20 nm or detect ions,” Kwak noted. “By converting the liquid sample into a gaseous aerosol state for detection, we can measure particles down to 1 nm, as well as ions and multi-particles.”

For example, when analyzing a muddy, salty water sample, traditional hydro-sol methods (laser scattering) can only detect the solid mud particles, not the dissolved salt ions. ICP-MS can accurately measure both but is not real-time. K-Nano's system, by converting the hydro-sol into a gaseous aerosol, can measure both salt ions and mud particles, classifying them by size.

“The drawback is that it cannot precisely determine the origin of the detected sodium ions—whether they come from salt or, say, instant ramen seasoning,” Kwak added. “Our device is intended as a complementary, real-time monitoring tool rather than a primary, precision diagnostic tool.”

Contributing to Technology Localization and Commercialization

K-Nano has already completed a prototype of its aerosol-based equipment, confirming its potential in semiconductor production processes. It is now moving toward commercialization in partnership.“We have secured patents for the sensor unit and plan to integrate our proprietary software. K-Nano will be responsible for maintenance, developing process recipes, and other specialized tasks moving forward.” Kwak explained.

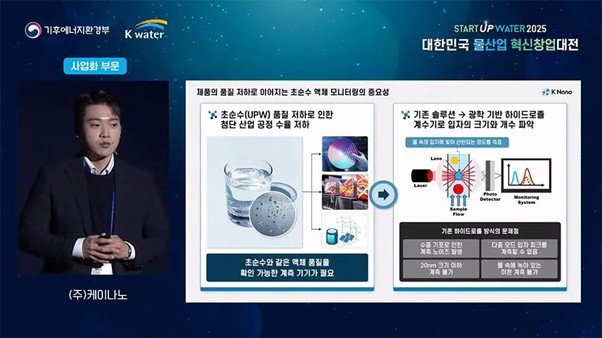

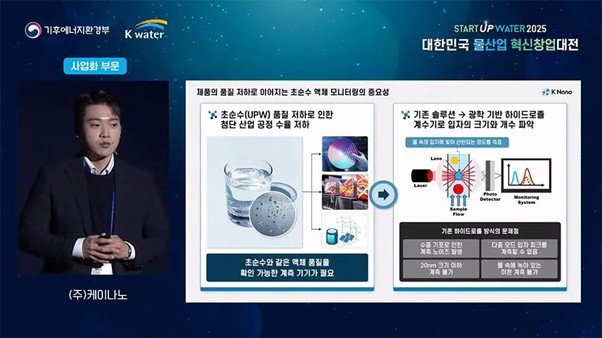

K-Nano Participated in the 2025 Korea Start-UP Water / source=K-water

The company’s entry into the commercialization phase has attracted support from key institutions, including the Korea Water Resources Corporation (K-water). K-water has been actively supporting R&D to secure domestic UPW equipment for the semiconductor industry for nearly a decade, aiming for a 90% domestic self-sufficiency rate by 2030, up from the current 70%.

K-Nano was recognized with the Excellence Award in the commercialization category at the 2025 Korea Start-UP Water in September. This success grants the company access to the "K-Testbed" performance testing facilities, support for participating in domestic and international exhibitions to scout new markets, and assistance in attracting investment through the Water Industry Fund.

SeoulTech’s Startup Support Foundation is also fostering K-Nano's growth. Kwak stated, “We’ve received multifaceted business and financial support, including the preliminary startup package. Our recent demo day provided opportunities to receive investment recommendations and feedback from investors. The foundation continues to provide platforms for business expansion, such as an invitation to the 2025 Creative Capacity Building Networking event on December 12th.”

The foundation also supported K-Nano’s participation in ILS 2025 (Innovation Leaders Summit) in Japan, one of Asia’s largest open innovation trade shows. Kwak mentioned, “From December 1st to 5th, we participated in ILS 2025, facilitating collaboration opportunities with major Japanese corporations. We discussed partnerships with companies such as Intercompo, Tokyo Electron, and YUASA Trading.”

SeoulTech supported K-Nano’s participation in ILS 2025 in Japan / source=K-Nano

Semiconductors as a Beachhead to Broader Industrial Adoption

K-Nano’s current aerosol monitoring device is specifically targeted at semiconductor manufacturers. Kwak is confident that success in the challenging semiconductor market will pave the way for adoption across other high-tech manufacturing sectors—including secondary batteries, displays, biotechnology, pharmaceuticals, precision chemistry, food, and cosmetics.

Kwak’s decision to tackle the semiconductor industry first stems from his background as a researcher at the Center for Filtration Research (CFR), where he focuses on the theory of filter media and system performance, as well as establishing filtration systems.

Introduction to the CFR, which establishes the theories and systems related to filtration. Kwak is also participating in this research and development / source=IT dongA

While CFR primarily involves environmental and consumer electronics companies, its roster also includes industry giants such as Applied Materials, Samsung Electronics, and LG Electronics, alongside filtration specialists like Pall Corporation, cleanroom air monitoring companies like TSI, and material simulation firms like Math2Market. Kwak plans to leverage his involvement in CFR research projects and networking to stay abreast of technological trends and promote K-Nano's capabilities to semiconductor firms.

K-Nano’s goal for the coming year is to successfully set up mass production and introduce its products to the global market / source=IT dongA

K-Nano’s goal for the coming year is the successful mass production of its product and its introduction into manufacturing processes, coupled with generating overseas demand.

“K-water’s support for domestic UPW technology has helped Korean companies gain international recognition,” Kwak stated. “Next year, our goal is to build a mass-production model and implement it in actual production lines. Based on that success, we plan to introduce the product to international companies. In 2027, we aim to participate in the UltraFacility Conference, the world's largest semiconductor monitoring equipment exhibition, to promote K-Nano's technology and strive to establish ourselves as the standard technology for liquid monitoring across various industries.”

By Si-Hyeon Nam (sh@itdonga.com)