ITED Embarks on Korea and Global Expansion with Transparent Heating Solution.

ITED Embarks on Korea and Global Expansion with Transparent Heating Solution.

Posted November. 28, 2025 16:36,

Updated November. 28, 2025 16:37

- ITED has developed a proprietary transparent heating technology using nanomaterials, which offers superior heating speed, efficiency, flexibility, and durability compared to traditional ITO-based solutions, and is being applied across industries such as automotive, heavy equipment, and construction.

- The company is expanding globally, conducting Proof of Concept projects with major OEMs in Europe and China, and aims to provide customized transparent heating systems for diverse applications including future mobility and robotics.

- ITED’s innovations address safety, energy efficiency, and visibility challenges, positioning the company as a comprehensive transparent heating solution provider.

ITED, a specialized enterprise in transparent heating materials, possesses a proprietary transparent heating technology based on nanomaterials. This technology demonstrates superior performance in heating speed, thermal efficiency, flexibility, and durability compared to traditional Indium Tin Oxide (ITO)-based transparent electrodes.

This innovation effectively resolves issues caused by temperature differences, such as condensation and frost. In the automotive sector, it removes frost and foreign substances from cameras and sensors, thereby enhancing object recognition accuracy. In heavy machinery, port operations, and railways, it secures operator visibility in winter and outdoor environments, significantly improving safety. In the construction sector, it is applied to daylighting and insulating glass to boost energy efficiency.

ITED is expanding the application scope of its transparent heating technology beyond automobiles, heavy equipment, ports, railways, and architecture to include future mobility, semiconductors, and robotics. The company is also actively pursuing entry into global markets, including Europe and China.

Possessing Transparent Heating and Manufacturing Process Technologies

ITED’s core technology is a transparent heating solution based on highly conductive nanomaterials. According to ITED, this technology combines a silver (Ag)-based nano-network structure with a self-developed process that minimizes contact resistance. The company explains that this results in higher heating speeds, thermal efficiency, flexibility, and durability compared to existing ITO-based transparent electrodes.

According to ITED, the transmittance is over 90%, similar to ITO-based electrodes, but the initial heating speed is two to three times faster. Thanks to a high-efficiency heating structure, it reaches maximum temperature rapidly. Furthermore, temperature rise efficiency is improved by 20–40% under the same power conditions, and heat distribution is uniform.

Flexibility has also been secured. While existing ITO-based technologies are prone to cracking when applied to curved surfaces, ITED’s transparent heating technology can be applied to lenses and curved glass. It is applicable to both films and glass, and its durability has been reinforced to maintain performance even in high-current and high-temperature environments.

ITED has also established production facilities for mass production. The company is equipped with Roll-to-Roll (R2R) conductive nanomaterial coating equipment capable of producing 1.2-meter-wide sheets, as well as R2R post-processing equipment that allows for continuous post-processing of these 1.2-meter-wide products. According to ITED, this facility is capable of producing the widest products in South Korea. Through this, ITED has reduced production costs by 30–40% compared to existing technologies and increased productivity fivefold.

Application Across Diverse Industries: Automotive, Heavy Equipment, and Architecture

Based on its transparent heating technology, ITED has commercialized heating films and heating glass. These products are being applied in various fields, including automobiles, heavy equipment, ports, railways, and construction materials.

In the automotive sector, the technology is utilized for vehicle camera cover glass and windshields. With the advancement of autonomous driving technology, the number of vehicle cameras and sensors is increasing. Consequently, securing visibility and accurate object recognition against snow, rain, ice, and frost has emerged as a critical issue.

ITED applies its transparent heating technology to cameras and sensors to secure clear visibility regardless of the surrounding environment and to increase object recognition rates. Through Proof of Concept (PoC) projects with automotive-related companies, ITED verified performance capable of reaching 65°C in approximately 10 seconds with uniform heating across both flat and curved surfaces. Currently, the company has completed PoCs with domestic and international automotive Original Equipment Manufacturers (OEMs) and is proceeding with full-scale vehicle application evaluations.

In the heavy equipment, port, and railway sectors, the technology is utilized as a solution for preventing condensation and frost. ITED has supplied large-area transparent heaters for container crane cabins, transparent heating glass for port cargo handling equipment, transparent heating films for subway stations and trains, and defrosting systems for railways and tunnels, validating performance in actual operating environments. ITED’s products are receiving positive feedback for: ▲ prevention and removal of condensation in high-altitude and outdoor environments ▲ rapid removal of frost, snow, and humidity in winter ▲ enhancement of safety by securing operator visibility. The ability to supply large-area transparent heating products is evaluated as a particular strength.

In the construction sector, the technology is mainly applied to skylights and insulating glass. ITED’s transparent heating technology is evaluated as a solution that aligns with Zero Energy and Passive House (energy-efficient buildings) policies through condensation and fog prevention, heating film attachment, and heating glass interfaces. Currently, ITED is conducting PoCs with domestic construction companies and is preparing for certification through the Korea Reliability Certification Center (KORAS).

Additionally, ITED is expanding its application scope to future mobility, semiconductors, and robots. Recently, the company was selected for the Ministry of SMEs and Startups’ "Super Gap Startup 1000+ (Future Mobility)" program for its non-contact sensor cleaning solution for autonomous vehicles. It is also participating in the Super Gap Open Innovation Promotion Support Program by the Seoul Business Agency (SBA). This program supports effective publicity for selected "Super Gap" companies to enhance their external public relations and marketing capabilities.

Actively Pursuing Domestic and International Market Expansion

ITED is also pushing for the global expansion of its transparent heating technology. Since early 2025, the company has been discussing OEM mass production verification and supply of transparent heating products with major companies in Europe and China. It has conducted PoCs with global companies in Germany, Spain, and Poland, and is currently discussing OEM supply and mass production. ITED’s strategy is to provide customer-customized transparent heating systems based on the references built from various PoCs and testbeds in Korea.

Along with this, ITED plans to expand its business area by introducing: ▲ high-performance transparent heaters for extreme environments ▲ smart coatings fused with additional functions such as Ultraviolet (UV) and Infrared (IR) blocking ▲ transparent heating cleaning solutions for sensors and cameras ▲ integrated heating modules for industry, mobility, and architecture. Through these initiatives, the company aims to leap from a transparent heating film manufacturer to a comprehensive transparent heating solution enterprise.

Jee-hoon Seo, CEO of ITED, stated, "While the need for transparent heating technology has existed, actual purchasing demand was not sufficient until now." He explained, "However, recently, domestic and international demand is surging as issues such as safety concerns due to visibility problems, cost increases due to energy loss, and risks in work environments are being highlighted." He emphasized, "ITED will grow into a company that responds quickly and accurately to the market based on numerous PoCs and practical experiences."

By Man-hyuk Han (mh@itdonga.com)

- The company is expanding globally, conducting Proof of Concept projects with major OEMs in Europe and China, and aims to provide customized transparent heating systems for diverse applications including future mobility and robotics.

- ITED’s innovations address safety, energy efficiency, and visibility challenges, positioning the company as a comprehensive transparent heating solution provider.

ITED, a specialized enterprise in transparent heating materials, possesses a proprietary transparent heating technology based on nanomaterials. This technology demonstrates superior performance in heating speed, thermal efficiency, flexibility, and durability compared to traditional Indium Tin Oxide (ITO)-based transparent electrodes.

This innovation effectively resolves issues caused by temperature differences, such as condensation and frost. In the automotive sector, it removes frost and foreign substances from cameras and sensors, thereby enhancing object recognition accuracy. In heavy machinery, port operations, and railways, it secures operator visibility in winter and outdoor environments, significantly improving safety. In the construction sector, it is applied to daylighting and insulating glass to boost energy efficiency.

Heating film featuring ITED's transparent heating technology / source=ITED

ITED is expanding the application scope of its transparent heating technology beyond automobiles, heavy equipment, ports, railways, and architecture to include future mobility, semiconductors, and robotics. The company is also actively pursuing entry into global markets, including Europe and China.

Possessing Transparent Heating and Manufacturing Process Technologies

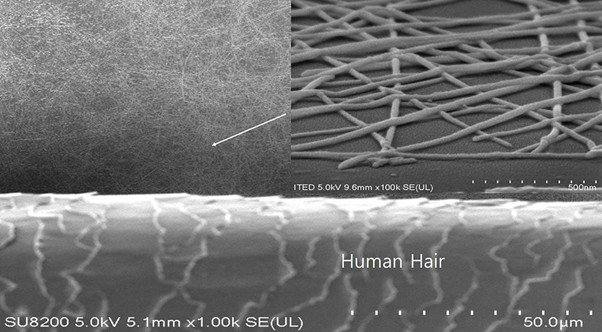

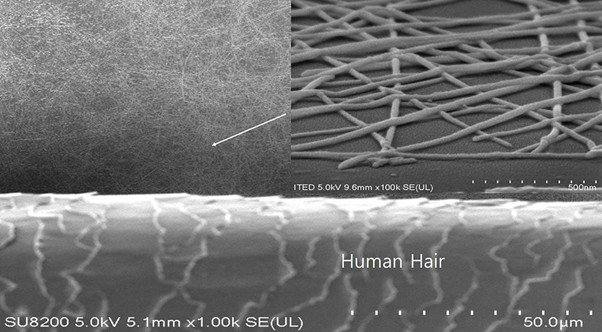

ITED’s core technology is a transparent heating solution based on highly conductive nanomaterials. According to ITED, this technology combines a silver (Ag)-based nano-network structure with a self-developed process that minimizes contact resistance. The company explains that this results in higher heating speeds, thermal efficiency, flexibility, and durability compared to existing ITO-based transparent electrodes.

According to ITED, the transmittance is over 90%, similar to ITO-based electrodes, but the initial heating speed is two to three times faster. Thanks to a high-efficiency heating structure, it reaches maximum temperature rapidly. Furthermore, temperature rise efficiency is improved by 20–40% under the same power conditions, and heat distribution is uniform.

ITED’s conductive nanomaterials, approximately 1/5,000th the thickness of a human hair / source=ITED

Flexibility has also been secured. While existing ITO-based technologies are prone to cracking when applied to curved surfaces, ITED’s transparent heating technology can be applied to lenses and curved glass. It is applicable to both films and glass, and its durability has been reinforced to maintain performance even in high-current and high-temperature environments.

ITED has also established production facilities for mass production. The company is equipped with Roll-to-Roll (R2R) conductive nanomaterial coating equipment capable of producing 1.2-meter-wide sheets, as well as R2R post-processing equipment that allows for continuous post-processing of these 1.2-meter-wide products. According to ITED, this facility is capable of producing the widest products in South Korea. Through this, ITED has reduced production costs by 30–40% compared to existing technologies and increased productivity fivefold.

Application Across Diverse Industries: Automotive, Heavy Equipment, and Architecture

Based on its transparent heating technology, ITED has commercialized heating films and heating glass. These products are being applied in various fields, including automobiles, heavy equipment, ports, railways, and construction materials.

In the automotive sector, the technology is utilized for vehicle camera cover glass and windshields. With the advancement of autonomous driving technology, the number of vehicle cameras and sensors is increasing. Consequently, securing visibility and accurate object recognition against snow, rain, ice, and frost has emerged as a critical issue.

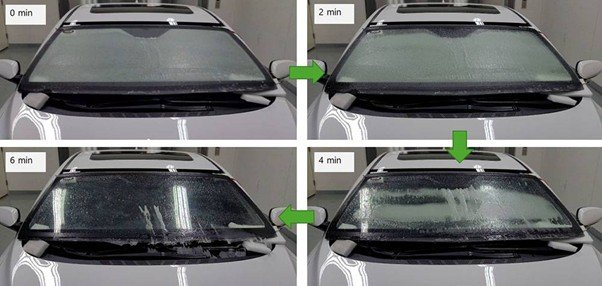

ITED applies its transparent heating technology to cameras and sensors to secure clear visibility regardless of the surrounding environment and to increase object recognition rates. Through Proof of Concept (PoC) projects with automotive-related companies, ITED verified performance capable of reaching 65°C in approximately 10 seconds with uniform heating across both flat and curved surfaces. Currently, the company has completed PoCs with domestic and international automotive Original Equipment Manufacturers (OEMs) and is proceeding with full-scale vehicle application evaluations.

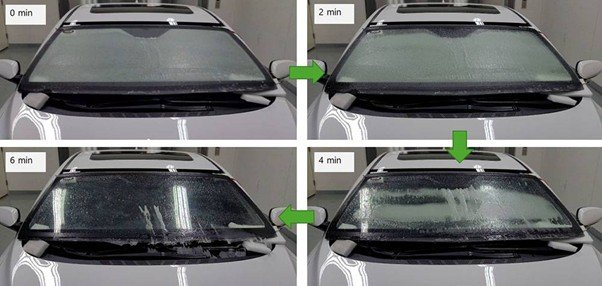

A vehicle windshield covered in 3mm-thick ice after exposure to -15°C conditions. The ice is completely cleared within six minutes of activation / source=ITED

In the heavy equipment, port, and railway sectors, the technology is utilized as a solution for preventing condensation and frost. ITED has supplied large-area transparent heaters for container crane cabins, transparent heating glass for port cargo handling equipment, transparent heating films for subway stations and trains, and defrosting systems for railways and tunnels, validating performance in actual operating environments. ITED’s products are receiving positive feedback for: ▲ prevention and removal of condensation in high-altitude and outdoor environments ▲ rapid removal of frost, snow, and humidity in winter ▲ enhancement of safety by securing operator visibility. The ability to supply large-area transparent heating products is evaluated as a particular strength.

In the construction sector, the technology is mainly applied to skylights and insulating glass. ITED’s transparent heating technology is evaluated as a solution that aligns with Zero Energy and Passive House (energy-efficient buildings) policies through condensation and fog prevention, heating film attachment, and heating glass interfaces. Currently, ITED is conducting PoCs with domestic construction companies and is preparing for certification through the Korea Reliability Certification Center (KORAS).

Additionally, ITED is expanding its application scope to future mobility, semiconductors, and robots. Recently, the company was selected for the Ministry of SMEs and Startups’ "Super Gap Startup 1000+ (Future Mobility)" program for its non-contact sensor cleaning solution for autonomous vehicles. It is also participating in the Super Gap Open Innovation Promotion Support Program by the Seoul Business Agency (SBA). This program supports effective publicity for selected "Super Gap" companies to enhance their external public relations and marketing capabilities.

Transparent heating glasses of ITED / source=ITED

Actively Pursuing Domestic and International Market Expansion

ITED is also pushing for the global expansion of its transparent heating technology. Since early 2025, the company has been discussing OEM mass production verification and supply of transparent heating products with major companies in Europe and China. It has conducted PoCs with global companies in Germany, Spain, and Poland, and is currently discussing OEM supply and mass production. ITED’s strategy is to provide customer-customized transparent heating systems based on the references built from various PoCs and testbeds in Korea.

Along with this, ITED plans to expand its business area by introducing: ▲ high-performance transparent heaters for extreme environments ▲ smart coatings fused with additional functions such as Ultraviolet (UV) and Infrared (IR) blocking ▲ transparent heating cleaning solutions for sensors and cameras ▲ integrated heating modules for industry, mobility, and architecture. Through these initiatives, the company aims to leap from a transparent heating film manufacturer to a comprehensive transparent heating solution enterprise.

Jee-hoon Seo, CEO of ITED, stated, "While the need for transparent heating technology has existed, actual purchasing demand was not sufficient until now." He explained, "However, recently, domestic and international demand is surging as issues such as safety concerns due to visibility problems, cost increases due to energy loss, and risks in work environments are being highlighted." He emphasized, "ITED will grow into a company that responds quickly and accurately to the market based on numerous PoCs and practical experiences."

By Man-hyuk Han (mh@itdonga.com)

![뜯은지 6개월 지나면 버려야…빨래 악취 원인은 ‘이것’ [알쓸톡]](https://dimg.donga.com/c/138/175/90/1/wps/NEWS/IMAGE/2025/12/04/132902127.3.jpg)

![숨 쉬는 공기조차 불평등하다…인도의 대기오염 재앙[딥다이브]](https://dimg.donga.com/c/138/175/90/1/wps/NEWS/IMAGE/2025/12/05/132909314.1.png)