Space&Bean, “Transition to new space, start with application of commercial parts”

Space&Bean, “Transition to new space, start with application of commercial parts”

Posted June. 12, 2024 13:52,

Updated August. 30, 2024 10:08

Cho Yang-chan, CTO at Space&Bean

The space industry was originally a product of state-led systemic competition during the Cold War. Recently, however, the space industry has been changing its paradigm led by private companies. This is because various business opportunities such as space tourism and low-orbital satellite networks are wide open. It is the opening of the so-called 'New Space' era.

As it is still a transitional period, there is also a challenge to be solved. One of them is the quality standard for 'space-class parts' tailored to the old space era. For existing satellites that remain in high orbit and perform long-term missions, the durability of protecting components from all kinds of harmful cosmic radiation and operating stably for a long time was of utmost importance. As it focuses on durability, it costs more than commercial products (COTS, Commercial Off The Shelf), but its performance decreases.

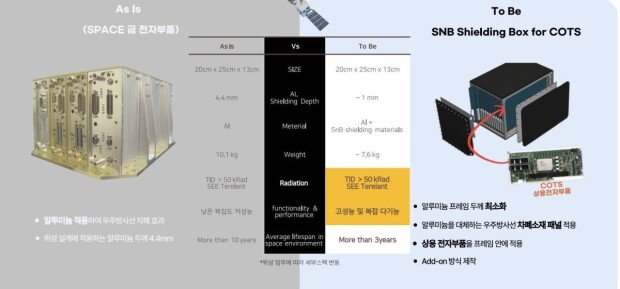

For this reason, some say that in order to revitalize the private company-led space industry, it is necessary to pave the way for the installation of commercial products on satellites by preparing new quality standards for the low orbit environment, the main stage of the new space era. Even if it is a commercial product, it has the minimum durability to operate in space, and if only the appropriate radiation shielding material is applied to it, it can play its role in a low orbit space environment.

As such, there is startup that are trying to pave the way for revitalizing the domestic private company-led space industry by laying the foundation for the satellite application of commercial products/parts. It is 'Space&Bean' that analyzes the space radiation environment and develops shielding solutions accordingly.

Cho Yang-chan, who leads research and development in the space industry as CTO at Space&Bean, was an officer from the Korea Military Academy who studied electronic engineering at Seoul National University in 1997 and spent most of his military life in research and development related to weapons systems such as communication weapons, drones and guided weapons in the defense industry.

He said, "Low-orbital and ultra-orbital satellites are cluster satellites that can function only when they are equipped with a large number of ultra-small satellites, not one or two. So they can operate economically only when they cost a lot. However, the quality standards required by our government for satellite components are still set for satellites that operate in space for a long time like existing geostationary-orbit satellites."

The life span of geostationary-orbit satellites is largely determined by the amount of fuel they fuel to maintain their orbit. It usually lasts 8-10 years, up to 12-13 years. On the other hand, low-orbital satellites are up to 3 years, an average of 3 years. Because of the short life span, more frequent replacements are needed. In this situation, applying the quality standards of high-orbital satellites to low-orbital satellites is like setting an engine of a big-sized sedan in a small car, said Cho.

And he said, "Because of the different radiation environments, the shielding performance of high orbit space and low orbit space is different. Most of the space radiation is the proton, the high orbit environment has 1,000 times more protons than the low orbit environment. It is unreasonable to apply the standard of 'space-class parts' that withstand more than 1,000 times the environment to low orbit satellite parts."

The benefits of using commercial parts for satellite fabrication are clear. Commercial parts are not only cheaper than space-class parts that focus on radiation resistance, but also perform better. A typical example is semiconductors. Cho said, "Currently, semiconductors such as memory used on the ground are very vulnerable to neutrons and gamma rays contained in secondary space radiation and have not been used for high orbital geostationary satellites," and "existing satellite semiconductors have focused on radiation resistance and have a long development period, so the technology gap with current commercial semiconductors is up to 20 years."

In this situation, Cho predicts that more can be done by putting commercial semiconductors on ultra-small low-orbital satellites. "The use of AI processors have recently been studied to improve the information processing performance and communication efficiency of low-orbital satellites," he said. "There are companies developing related AI processors in Korea."

What is needed to load and launch these commercial parts on satellites is the solution being developed by Space&Bean. Space & Bean has the know-how and technology to analyze the low-orbital radiation environment and internal radiation resistance of commercial parts and apply appropriate shielding materials.

For example, aluminum, which is mainly used as a shielding material for existing satellites, prevents primary radiation well but is vulnerable to secondary radiation. So, to use commercial parts such as AI semiconductors, other materials that can minimize secondary radiation are needed. Then Space&Bean has developed polymer-based composite materials. Cho explained, "If implemented with the same shielding performance, it is one-third lighter than aluminum, which can also reduce the cost of launch."

Space&Bean are also developing their own satellites to measure and verify the performance of commercial parts with these shielding solutions. The goal is to establish a platform to secure a verification history(heritage) from the application of shielding solutions for commercial parts through satellites.

They are also promoting industry-university cooperation. Space&Bean is conducting a 'cube satellite development contest for measuring the performance of space radiation shielding for the application of satellite COTS parts' for Korean university students and graduate students. The selected teams will be given prize money or equivalent material support, education programs, and opportunities to attend cube satellite flight tests.

Space&Bean aims to apply this shielding solution and verification system to the military through the 'spin-on' system which applies civilian technology to the defense sector. This opens the way for commercial parts of private companies to be applied to low-orbital satellites in the defense sector.

Cho said this defense applications will also make it easier to enter a much larger global private space industry market. "The demand for commercial parts on low orbit satellites is high overseas, and the demand for satellite launch is also higher overseas than in Korea," and "The demand for the launch of small and ultra-small satellites will increase further in the future, and considering the demand for re-launch due to failure, more satellites will be launched in the future than expected."

by Kwon Taek-kyong (tk@itdonga.com)